The METALOQ system is reshaping the construction industry with its innovative modular kit frames, suitable for buildings from 4 to over 10 stories. This system offers precision assembly through features like proprietary clamped joist connections and autonomous locking mechanisms. Designed to integrate elevators and stairs, it guarantees functionality and versatility. Fabricators benefit from durable, galvanized materials and ultra-low scrap rates, making production efficient. Investors and modular builders can leverage patent-pending technology available in 49 countries. A revolutionary approach to construction is at your fingertips, promising efficiency and sustainability like never before. Explore further to understand its full potential.

Key Takeaways

- METALOQ Kit Frames enable rapid, offsite construction of high-rise buildings with easy, efficient assembly.

- The system features precision locating and autonomous locking for reliable and quick module connections.

- Specialized components for elevators and stairs enhance the functionality and versatility of METALOQ structures.

- Fabricators benefit from ultra-low scrap rates and simplified production without the need for new technologies.

- METALOQ’s patent-pending technology offers lucrative partnership opportunities for investors and modular builders worldwide.

METALOQ Kit Frames

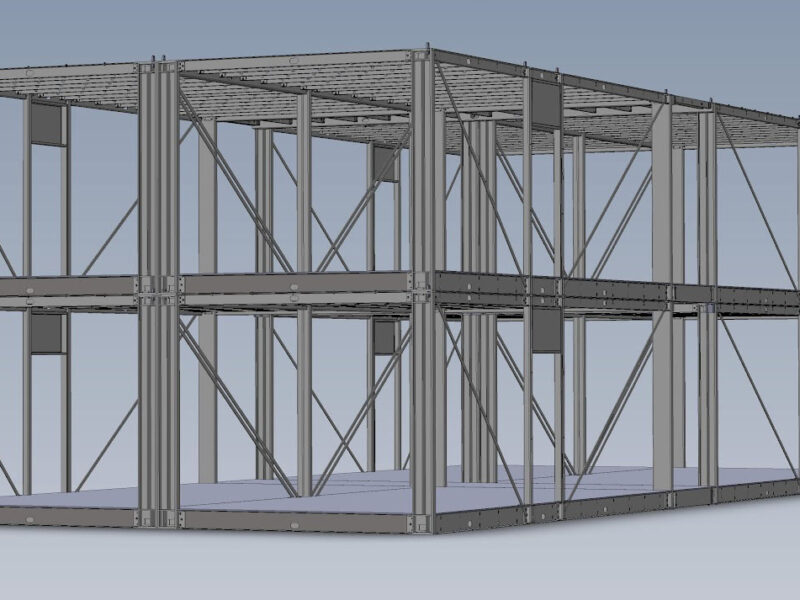

METALOQ Kit Frames provided by Lanex Manufacturing represent the pinnacle of efficiency in modular construction, delivering stackable structures for buildings ranging from four to over ten stories.

As the industry’s most efficient structural connection system, METALOQ frames revolutionize offsite transformation with their ease of assembly, requiring no specialized tradespeople. This innovative approach allows for swift, precise construction, making it ideal for rapid urban development.

The system’s patent-pending status in 49 countries underscores its groundbreaking impact on the industry. By enabling scalable, robust structures, METALOQ frames set a new standard in modular construction, offering unparalleled flexibility and efficiency.

This solution addresses the growing demand for sustainable, high-rise buildings with a focus on both quality and speed.

Key System Inventions

Among the notable innovations within the METALOQ system are precision locating features that guarantee reliable assembly. These features ensure the accurate placement of components, facilitating seamless integration with minimal margin for error.

The proprietary clamped joist to rim joist connection delivers unparalleled fixity, enhancing structural stability.

The taper-lock horizontal module interconnector allows for precise, robust connections between modules, ensuring a cohesive build.

Additionally, the autonomous locking system revolutionizes assembly by enabling modules to lock into place automatically.

This is complemented by autonomous MEP connections, which eliminate the need for extensive on-site work.

These inventions collectively simplify the construction process, reduce labor costs, and increase overall efficiency, marking a significant leap forward in modular construction technology.

Latest Innovations

In the latest series of advancements, the METALOQ system now includes the capability to integrate elevators and stairs through the use of three specialized components. This innovation underscores METALOQ’s commitment to transforming the modular construction landscape.

By seamlessly incorporating these vertical mobility solutions, METALOQ enhances the functionality and versatility of its kits, setting a new standard in offsite construction technology. The novel components are designed for rapid assembly, leveraging precision locating features and autonomous locking systems to guarantee dependable and efficient installation.

This forward-thinking approach not only simplifies the construction process but also expands the range of applications for METALOQ structures, solidifying its position as a leader in modular building innovation.

Advantages for Fabricators

Steel fabricators stand to gain significant benefits from the METALOQ system, including the ability to produce components without the need for new technologies.

The system’s use of galvanized material guarantees durability while keeping manufacturing processes straightforward. Ultra-low scrap rates enhance material efficiency, reducing waste and costs.

Additionally, METALOQ components are designed to withstand stringent conditions, such as Florida’s high wind speeds for 10-story buildings. The ease of assembly with just a small crew and basic hand tools streamlines operations, making the system highly accessible.

Moreover, the inclusion of cementitious or concrete floors offers flexibility and robustness, empowering fabricators to meet diverse construction demands effectively and innovatively.

Partnership Opportunities

The METALOQ system presents a unique opportunity for investors, steel fabricators, and modular builders to engage in transformative partnerships that will drive the future of construction.

This revolutionary system, with its patent-pending technology in 49 countries, promises to advance the modular industry by offering precision and efficiency.

Investors can capitalize on licensing and manufacturing opportunities, while steel fabricators benefit from ultra-low scrap rates and simplified production.

Modular builders can leverage METALOQ’s stackable frames and autonomous MEP connections to streamline on-site assembly, reducing labor costs and construction times.

Recent Comments